I actually completed my EPAS installation some time ago, but only now got around to documenting it. Once I got the fitment of the steering column straightened out the EPAS install went well. I did run into several other issues while buttoning everything up. One issue was related to the Ididit steering column. The other issue was with my clutch linkage. The clutch linkage was not directly related to the EPAS install. It only became an issue with the EPAS installation because I had decided to remove and replace the linkage at the same time as the EPAS install. Replacing the clutch linkage was not required by the EPAS installation.

After I got the EPAS motor and steering column situated under the dash with the proper clearance I installed the stalks for the turn signals and tilt mechanism. Next, I did another test of the steering column wiring. The turn signals, horn, emergency flasher, and brake lights were all working properly. I was finally making good progress, and my next step was to install the steering wheel.

My car originally came from the factory with a deluxe steering wheel. When I purchased the car the original steering wheel was in the trunk and was badly broken. I had purchased an original standard wheel years ago and had used it until it cracked badly. At that time, I was able to locate a used deluxe steering wheel that had been restored. That is the steering wheel I had been using since getting the car back on the road in 2013. I liked the original look but had decided to treat myself to an upgrade to go along with the new steering column.

The new steering wheel I eventually selected and purchased is a Corso Feroce reproduction of the Shelby mustang wood grain steering wheel. It had the look I wanted, was made with real rather than simulated wood, and didn’t require an adapter to install. I love the look of this wheel. It has a horn button in the center rather than on each spoke like the factory deluxe wheel. This should eliminate my accidentally honking the horn when backing up and turning the wheel with one hand. I didn’t want to have a Shelby logo on the horn button as My car isn’t a Shelby. But I could order a standard Mustang emblem on the horn button. The only things I might change is for the wheel to be thicker and maybe a smaller diameter.

Here is a picture of the Corso Feroce steering wheel with the horn button I selected.

I installed the new steering wheel and torqued it down. Unfortunately, it bottomed out on the steering column and completely bound up. I removed the wheel and tried both of my original wheels. They both also bottomed out on the column. I had both my original steering column and a column out of a 1968 Mustang. All three wheels fit fine on both of the original steering columns. Time to call tech support.

This is a picture showing the lack of clearance between the steering wheel and the column. The bolt is only finger tight when this picture was taken.

I contacted tech support at EPAS Performance and described the issue. They told me that they have seen that problem before and that I should contact Ididit for a spacer that would correct the problem. When I contacted Ididit, they told me they have never seen this issue before and that all three of my steering wheels must be defective. After a lot of back and forth including pictures and measurements, Ididit’s recommendation was to use a FlashPower steering wheel adapter and an aftermarket steering wheel. I wasn’t willing to change to yet another steering wheel as I really liked the Corso Feroce wheel.

I did some searching on the Internet and found two people with a similar steering column. One said he used the FlashPower adapter and an aftermarket steering wheel. The other person used a stock steering wheel and had the same issue thst I was having. He had to do some grinding for clearance. I ended up doing a bit of clearancing and also built up the inside of the steering wheel. At that point I was able to torque everything down with no interference. A short test drive proved that the power assist steering was working. Unfortunately, the lower clutch rod came apart near the end of the test ride. I was able to limp my way home by clutchless shifting, a skill I learned in this car decades ago. The couple of times I had to come to a complete stop, I started the car in gear. I’m sure this didn’t do the starter any good, but it survived the trip back home.

So now it was time to install the OpenTracker lower clutch rod which I had deferred earlier in the EPAS install. I removed the z-bar and drilled out the hole for the new lower clutch rod. Then I went to screw the bullet adapter on to the lower clutch rod. The thread pitch on the new rod was fine thread but the adapter was coarse thread. After a few conversations with John at OpenTracker, I ordered a replacement adapter that was not threaded. John offered to send me one no charge, but I had already ordered the threadless one. Once that arrived, I installed the new lower clutch rod and adjusted the clutch. The clutch linkage operates nice and smooth now.

Here is the original lower rod (top), the OpenTracker rod (bottom), and the original threaded bullet adapter.

This is the new bullet adapter I ordered. It has no threads.

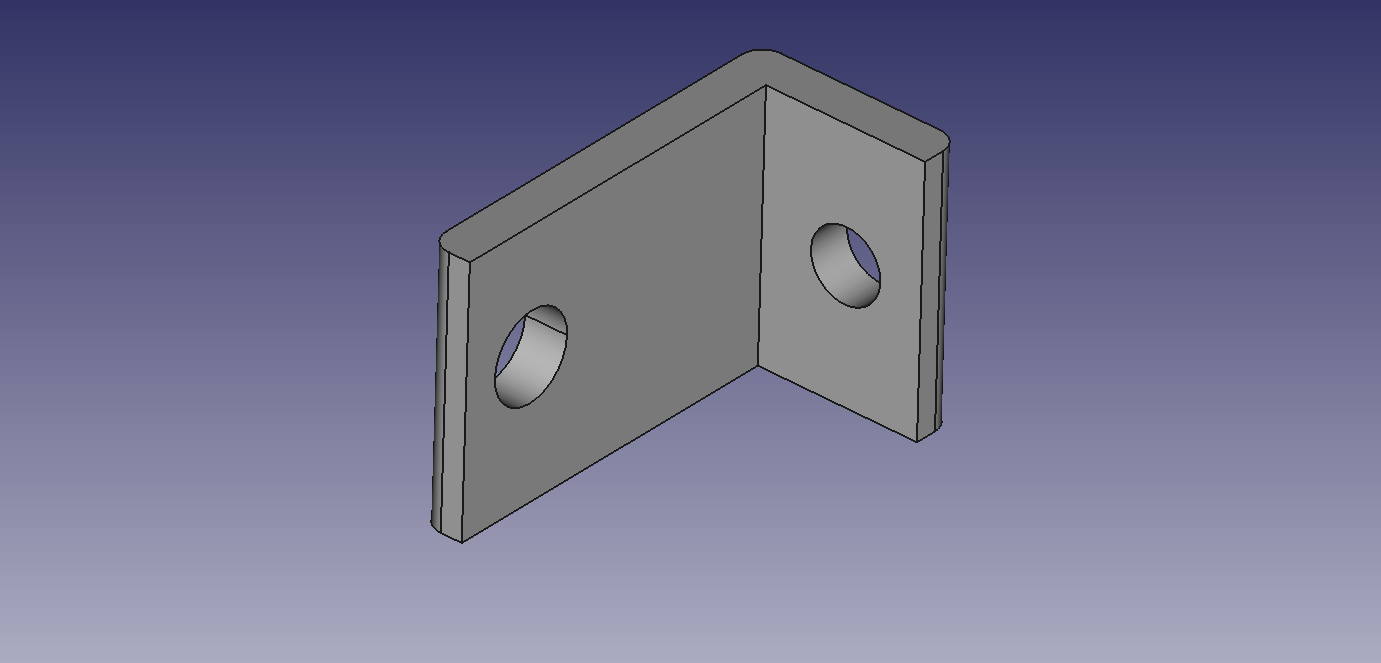

There was now only one more thing to address which was where to mount the potentiometer that controls how much steering assist the EPAS system provides. I had recently purchased a 3D printer, so I decided to print a bracket for the potentiometer that mounts under the dash. Since I am only learning how to use 3D CAD applications, designing the part took some time and trial/error. Eventually I came up with a design I liked, printed the bracket in white, and installed the potentiometer. I will eventually reprint the bracket using red filament to match my dash, but for now I want to test the design and make sure it doesn’t interfere with anything and isn’t in my way.

This is an image of the bracket I designed.

At this point it is well into the driving season, and I have a lot of other non-car related projects to work on. Unless something breaks, anything else will have to wait until I get to working on my winter Mustang projects.