In January 2013 I retired from my job of many years. I had several plans for what I would do during retirement, but one was to fix up my house by repairing many of the things that had been neglected over the years. This led to some wall patching, painting, minor electrical, and plumbing work. Eventually it reached a point where my wife and I couldn’t agree on some of the projects, so work ground to a halt. A little while later I decided to shift gears and return to working on my old Mustang that had been sitting in the garage for the past 15 years or so.

I hadn’t been completely neglecting the car over all of those years. I had been very slowly and quietly purchasing and squirreling away parts in preparation for the day when I could work on the car again. I had some mechanical parts, some body trim, and the better part of the interior stashed away in my garage and basement. A few of the parts were even NOS Ford parts that are no longer available. But the majority of the interior parts are reproductions.

I knew the car required a lot of work after sitting so long. I felt that the best thing for me to do was to join the local Mustang club and start looking for referrals from them on resources to work on my car. I went ahead and joined the National Capitol Region Mustang Club, or NCRMC. I had been a member of that particular club back around 1983 or so, but I had let my membership lapse as I was never very active and at the time a lot of the club activities seemed to be in Virginia. I filled out an application and sent them the dues for one year. Step one completed.

Looking over the club’s Web site and reading through their recent newsletters and forum postings I learned that one of their members not only worked on the cars but he also permitted the owner to work and learn along with him. This sounded like exactly what I wanted. I didn’t feel like I could work on the car at my house and was planning on farming a lot of the work out to a competent mechanic. To have the opportunity to learn from somebody with a significant amount of experience sounded like the best of both worlds. The mechanic’s name was Val and I gave him a call.

The phone conversation with Val went really well (at least in my opinion). He was very knowledgeable and a really nice guy. And even better, he was willing to help me get my car back on the road and ensure it was safe to drive. The only catch was that he was booked up and couldn’t get to my car for about two months. That was OK by me as it would give me an opportunity to inventory what parts I had purchased, what I had gotten back from the restoration shop, and what I still needed to purchase.

I went through all the parts I could locate and made a list. I also made a list of what work I wanted to do, what order I planned to get it done, and what parts I needed. This left me with a list of parts to purchase and the order I needed the parts in. I scoured the Mustang parts vendors to find the best prices. Then I started placing orders for some of the parts in batches. What parts were included in a batch were pretty much dictated by when I needed them, what vendor carried them, and which vendor was having a sale. I worked pretty hard at making sure I got the best prices by waiting for the vendors to have sales or discounts. My parts collection was growing larger and larger.

There were still a few parts that were not available new and not being reproduced. For those parts I remembered a used parts vendor, Dave at Pony Express that I had done business with before back in the 1980’s. It turned out that he is still in business, although his location has changed. I was able to pick up some interior trim panels from him, and I will most likely need some more parts from him as I go. I also discovered that some parts that weren’t reproduced and had been hard to find used in decent condition were now being reproduced. I made note of the parts and corresponding vendors so that I know where to find them when I need them. Things really seemed to be coming together.

I waited patiently for the time to pass. I also did some minor work on the car in preparation. I bought a new battery as the old one was completely dead. I cleaned up and polished some of the trim that was still on the car. The tires were flat and when I tried to put air in them it quickly leaked out. They were too badly dry rotted so I bought a set of tires online. I had them shipped to the local tire store. Then I put on end of the car on jack stands, took off the wheels, took them to the store to have the tires mounted and balanced, and then put the wheels and new tires back on the car. Lather, rinse, and repeat for the other end of the car.

Then I got ambitious and drained the gas tank of the extremely bad smelling liquid that was in the tank. It used to be gas, but it wasn’t anymore. This took a couple of trips to the hazardous waste disposal site. Then I removed the tank and took that to the disposal site as well. I ordered a new tank and all of the hardware and caulk needed to install the tank. While cleaning out the lip where the tank mounted I crawled under the car and noticed that both of the mufflers had rusted through. Then I saw that part of the tail pipes weer rusted through as well. That meant I needed to include a new exhaust system in my list of parts to replace. I looked around some more underneath and noticed that the driver’s side trunk drop off was pretty rusted as well. I let Val know and he recommended that I not install the new tank as repairing the rust and replacing the exhaust would be easier with the tank removed. That put the new gas tank installation on hold. I put the new tank in place but didn’t bolt it in permanently.

Finally it was time to check in with Val. He said that he needed more time for the car he was working on and would let me know when he could get my car in. I went off and ordered a few more parts as a consolation. Periodically I would check in with Val and each time he said that he was still working on the same car. Finally, four months after I had first contacted him he said he was ready for my car and would come out with a trailer to pick it up. Mother Nature decided to intervene at this point and unleashed with some snow. So we had to delay once again. It seemed like every time Val planned to come by to pick up the car the weather interfered. Then Val let me know that he had a standing obligation to do some charity work every year in the Spring. Everything had been delayed so much that he was now under the gun to get that work done, and the dates couldn’t move. So my car would be delayed once again for about another 6 weeks or so.

At this point Val’s best recommendation was to either just wait for him to fit me into his schedule, or to start some of the work on my own and get back with him in 6-8 weeks. I wasn’t really too sure what I could reasonably hope to accomplish with my limited facilities and HOA restrictions. But I agreed that this was the course of action that made the most sense. I went back through my list of labor to be done and separated out what I might be able to accomplish on my own.

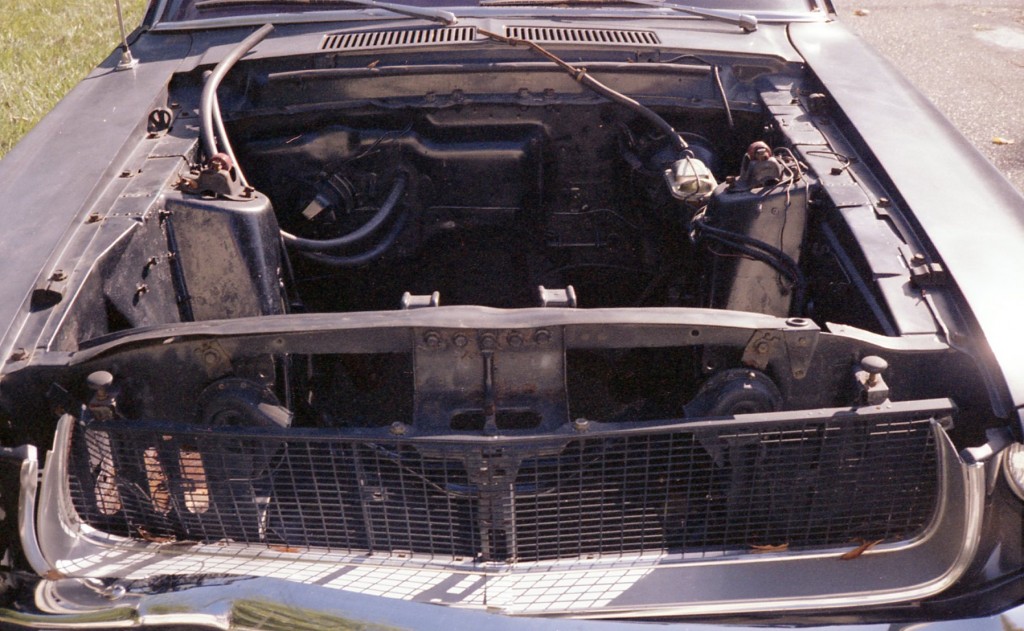

One evening on my way over to Jimmy’s house I was involved in a minor accident. Some damage to the front bumper, grille, and hood. Nothing that couldn’t be fixed, but it was fairly upsetting at the time. Here’s a picture after the accident showing some of the damage.

One evening on my way over to Jimmy’s house I was involved in a minor accident. Some damage to the front bumper, grille, and hood. Nothing that couldn’t be fixed, but it was fairly upsetting at the time. Here’s a picture after the accident showing some of the damage.