My Mustang still has the original style sealed beam headlights. They were never particularly bright, but I had learned to live with them. For years the only alternatives seemed to be halogen sealed beam replacements. I never bothered to upgrade in the past, but decided to see what my options are considering the improvements that have been made to lighting since the 1980’s.

The sealed beam halogen replacement bulb is still an option. It is probably better than my pair of old sealed beams, but based on some of my research it may not be much better than a new pair of sealed beam units. A really nice upgrade is to the newer H4 type of headlight. This is the same as used on my 1997 Mustang. I know that HID and LED conversions also exist, but the legality of these conversions is questionable. I also would like a stock appearing unit, so the H4 conversion seemed to be the best choice.

To upgrade to an H4 bulb I needed to purchase some glass housings that bolt in the stock location and accept the newer H4 bulb. I found a couple that I liked. One was made by Hella and the other was Cibie/Valeo. Some research on candlepower forums revealed that the Cibie unit was a better choice due to their light pattern. Also for me I liked the look better as it was less flat than the Hella, although they both look fine. I also looked at bulbs and settled on the Phillips X-Treme Vision based on their performance and that I got a really good price on them. I went ahead and ordered the housing and bulbs and continued to plan.

One of the issues with upgrading the lighting on older Mustangs is in the headlight wiring harness itself. The current for the headlights has to make its’ way to the headlight switch and dimmer switch in the car’s interior, then back to the headlights. With old wiring and the length of the wiring, voltage drop can be introduced. That’s one issue. The current carrying capacity of the stock wiring is the second issue. The newer and brighter headlights can sometimes require more current than the car’s wiring is designed to handle. The headlight switch contains an auto-resetting thermal circuit breaker to protect the headlight circuit. The increased current can trip the breaker causing the headlights to turn off. Once the breaker has cooled off it turns the headlights back on until the breaker heats up again. This causes a blinking affect where the headlights turn on and off when in use. This is obviously not acceptable.

The cure for this problem is to use the existing factory headlight wiring as a low current switching circuit and adding a new circuit to handle the increased current. This allows the existing switches to control the lighting the same as it always has, but provide more current carrying capacity for the headlights. The higher current wiring will also be much shorter decreasing the voltage drop from the original wiring. The way to accomplish all of this is to install headlight relays that are turned on and off by the existing wiring. The high current is switched on and off by the relays. I also chose to install higher current circuit breakers to protect the new wiring. The original breaker in the headlight switch would provide the protection for the low current part of the wiring.

My next decision was how best to wire up the new higher current circuit. I chose to go with overkill and install separate relays for each side of the car along with separate circuit breakers. I have seen many instances where one pair of relays is used to power both lights. Two relays are required because there is separate wiring for the low and high beams. I wanted to isolate the two headlights from each other in case of a failure in one side of my new wiring. Looking back on it now I think this may have been unnecessary but that’s my thinking and approach.

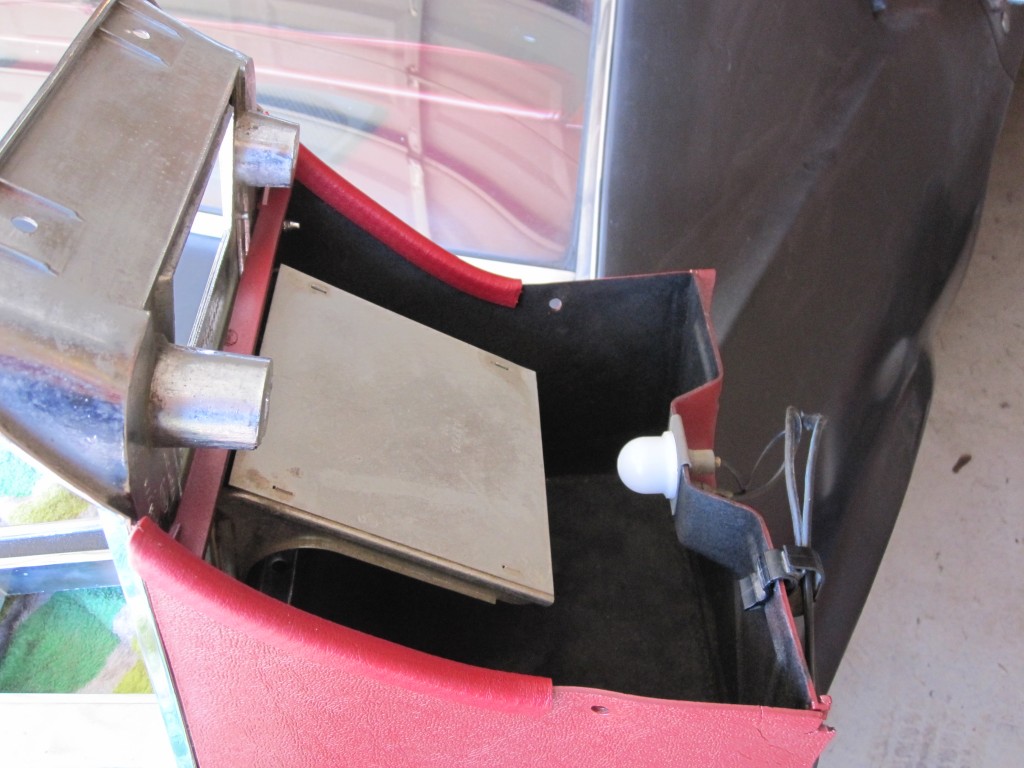

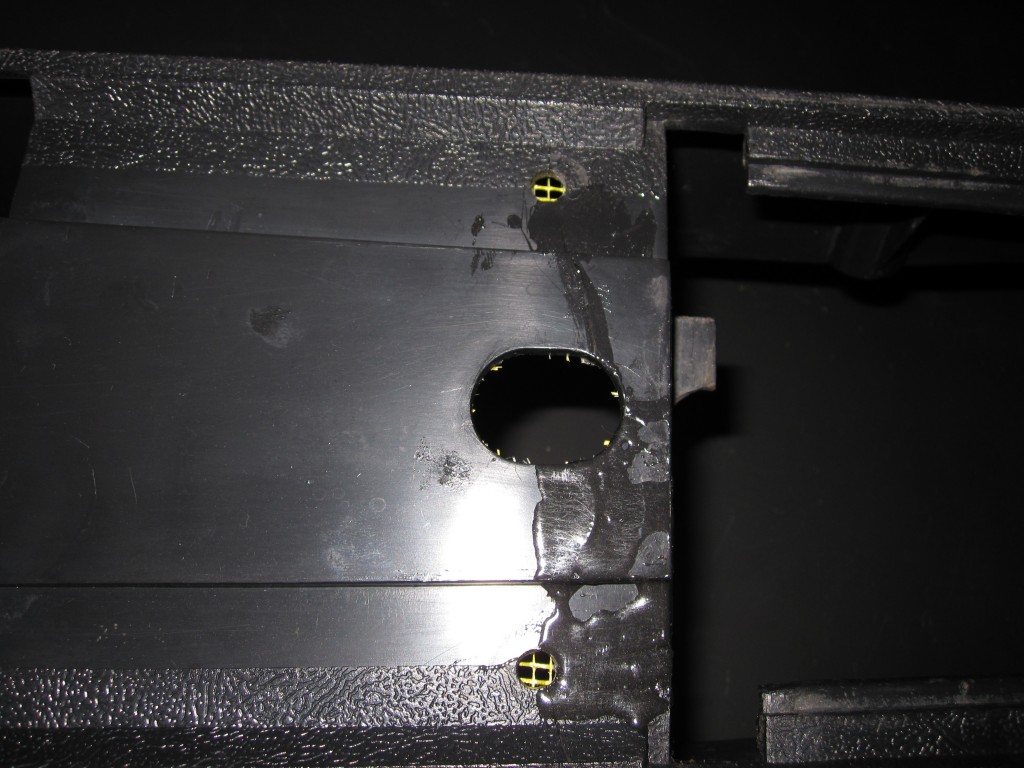

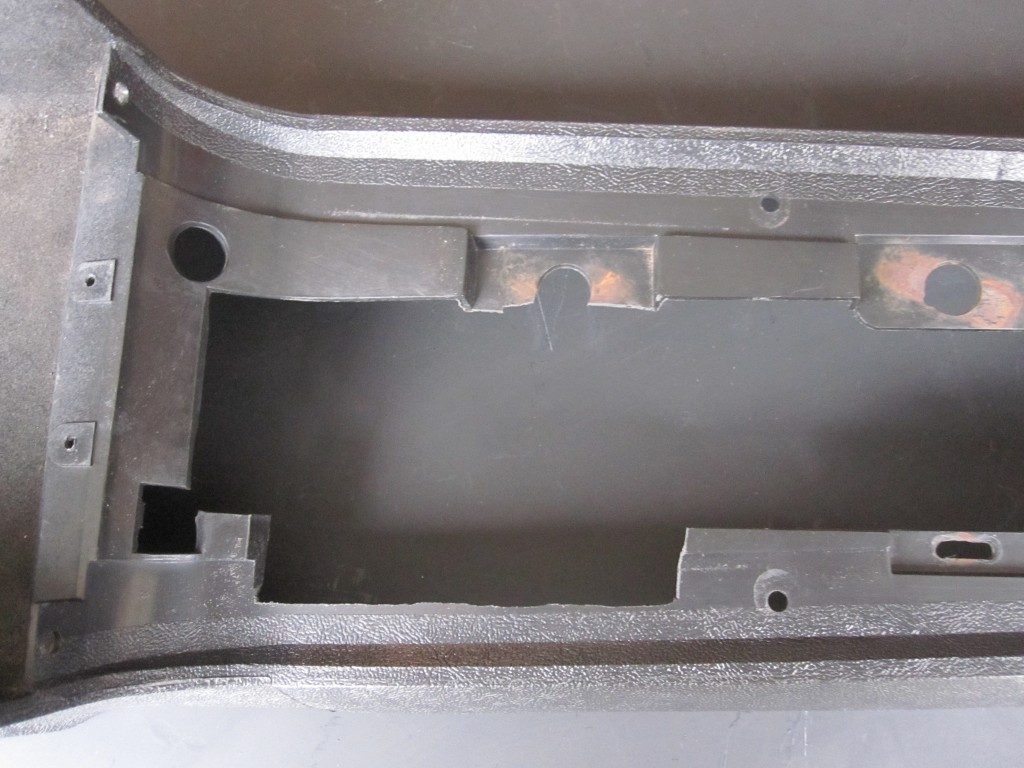

I planned to install a pair of relays and a circuit breaker in each of two project boxes and then wire them into the headlights. I also planned to run 12 volts from the starter solenoid to power the circuit. Getting the 12 volts was easy enough and so was filling the boxes. The question now was where to insert this into the existing headlight harness. I had seen three different approaches used.

The first approach was to splice into the existing harness and solder in new connections. I didn’t really want to cut up my existing harness so I discarded this approach without any more consideration. Looking back on it now it also had the disadvantage of reusing part of the existing wiring for the high current portion of the circuit. I’ll explain more about why I think that is a problem in a minute.

The second approach was to purchase an upgrade wiring harness that used the existing headlight plugs to trigger the relays and used new ceramic headlight connectors and bigger gauge wiring. This had the advantage of using the bigger gauge wiring for greater current carrying capacity along with the ceramic headlight connectors with greater heat tolerance. I have heard that the original plastic headlight connectors can sometimes melt from the increased heat of the upgraded lighting. So from a safety standpoint this sounded pretty good. The downside is that it takes a bit of effort to remove if the stock look is required for shows. Not too bad but the third approach I looked at was a lot more “plug and play”.

The third approach is to insert the new headlight boxes I was building in between the headlight wiring harness and the headlight extension wiring. This would make it very simple to install and remove the relay wiring, as I only needed to separate one plug on each side of the car and insert my new wiring. If I needed to remove it for any reason I could just unplug my relay box and plug the original wiring back together. This looked like a great approach and I made plans to build everything this way. But then I realized that the original headlight extensions used smaller gauge wiring and a plastic headlight connector. I really felt it was important to have the heavier gauge wiring and ceramic connectors for safety. So I returned to method number two.

I have almost all of the parts in hand but won’t be completing the project until my car is back from paint. I can begin building the relay boxes and some of the wiring, but I need the car here so that I can take some measurements and find where I have room for the relay boxes and wiring. This project isn’t a really high priority at this point, but just a “nice to have” item. I’ll continue to work on it as time permits and will come back and post some photos when I get a chance. Hopefully I’ll have the car back from paint in the next week or two.